Enhancing PTFE Performance - Ekanol, ATSP and their synergies in PTFE properties

- Updated on :

- Poly Fluoro Ltd

- Comment

Material science has always relied on the synergies between two disparate materials to create a whole that is far greater than the sum of its parts. In this manner, PTFE is no different.

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, has revolutionized various industries with its exceptional chemical resistance, low friction properties, and high-temperature stability. Despite its remarkable attributes, engineers and material scientists are constantly seeking ways to further enhance its performance for specific applications. In addition to this, processors, eager to protect their market, have often resorted to special formulations that offer unique properties that only they would know how to replicate.

Over time, fillers of bronze, glass, and carbon became regularised within PTFE, lending well understood boosts in wear properties, creep, and dimensional stability. However, two promising fillers, Ekanol and ATSP, have emerged as potential game-changers in the world of PTFE.

Ekanol: A Breakthrough Filler

Ekanol, a proprietary carbon-based filler, has gained significant attention for its ability to enhance the mechanical properties of PTFE. The introduction of Ekanol into PTFE formulations has been shown to improve wear resistance, tensile strength, and thermal conductivity.

One of the key advantages of Ekanol is its ability to act as a reinforcing agent. By compounding Ekanol with PTFE, the resulting composite material exhibits increased tensile strength, making it suitable for applications requiring higher mechanical performance. Additionally, Ekanol-filled PTFE demonstrates enhanced wear resistance, addressing a common concern associated with pure PTFE in applications subjected to friction and abrasion.

Furthermore, the thermal conductivity of PTFE is significantly improved with the addition of Ekanol. This enhancement is crucial for applications where efficient heat dissipation is essential, such as in electrical insulators or components of high-performance machinery. The synergistic combination of PTFE's intrinsic properties and Ekanol's reinforcing characteristics opens new possibilities for the material's application in diverse industries.

Aromatic Thermosetting Polyester (ATSP): A Leap Forward in Dimensional Stability

ATSP, an aromatic thermosetting polyester, introduces a distinct set of advantages to PTFE when used as a filler. This nanostructured material has shown promise in enhancing electrical properties and dimensional stability, making it a valuable addition to PTFE composites.

One of the standout features of ATSP is its ability to impart excellent dielectric properties to PTFE. This positions ATSP-filled PTFE as an ideal candidate for applications in the electronics and telecommunications industries, where high electrical insulation is paramount. The nanostructured nature of ATSP ensures a uniform distribution within the PTFE matrix, contributing to consistent and reliable electrical performance.

Beyond electrical properties, ATSP significantly improves the dimensional stability of PTFE. This is especially crucial in applications where precise tolerances and minimal expansion or contraction over a range of temperatures are essential factors. The incorporation of ATSP mitigates the effects of thermal expansion, providing a more stable material suitable for aerospace, automotive, and other demanding environments.

Synergy Unleashed: Ekanol and ATSP in Combination

Recent research has explored the synergistic effects of combining Ekanol and ATSP as fillers in PTFE, unlocking new dimensions of material performance. This innovative approach aims to harness the individual strengths of each filler, creating a PTFE composite with a well-balanced set of properties.

The combination of Ekanol and ATSP presents a harmonious blend of mechanical strength, thermal conductivity, electrical insulation, and dimensional stability. This opens up avenues for applications where a comprehensive set of properties is essential, such as high-performance gaskets, seals, and bearings used in critical industrial machinery.

Conclusion

The incorporation of Ekanol and ATSP as fillers in PTFE marks a significant stride in the evolution of advanced materials. These fillers not only address specific limitations of PTFE but also open up new possibilities for tailored applications in diverse industries. The synergistic effects observed when combining Ekanol and ATSP highlight the potential for creating PTFE composites with a broad spectrum of enhanced properties. As research continues to unravel the full potential of these fillers, the future holds exciting prospects for PTFE and its role in shaping technological advancements across various sectors.

Read More

1. Optimizing Solar Tracker Bearings for Enhanced Solar Energy Harvesting

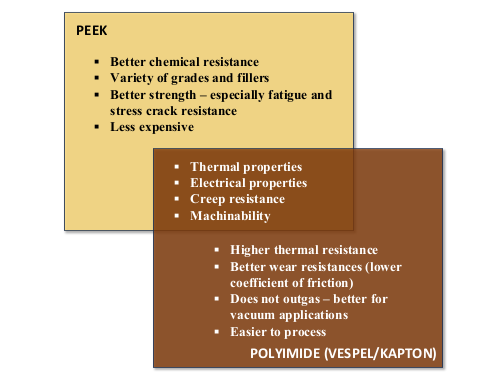

2. PEEK Vs Polyimide - Comparing Two of the Toughest Polymers

3. PTFE Extrusion - Ram vs Paste Extruded - A comparison of features