PTFE Thick-walled Tubes - Applications & Manufacturing Challenges

- Updated on :

- Poly Fluoro Ltd

- Comment

The use of PTFE tubes has become quite widespread across industries. As the scale of manufacture of regular thin-walled PTFE tubes has expanded, the cost has become less prohibitive. As a result, applications that were sensitive to the price of PTFE tubes have been able to adopt them.

In truth the properties exhibited by these thin-walled tubes are so diverse, that there is nearly no application where it cannot enhance the efficiency of a system. We have looked before at the overall properties of PTFE tubes and its application across various industries. However, we want to explore further the properties and challenges of thick-walled PTFE tubes.

Challenges in making thick-walled PTFE tubes

PTFE is a material that is challenging to process. Standard moulding processes that can be applied to what we call ‘melt processable plastics’ do not apply. Since PTFE does not melt, it cannot be converted into a liquid form and passed through a die. Instead, other methods are employed to achieve the shapes and profiles needed.

The processes for making PTFE tubes include:

-

Paste extrusion – where the PTFE powder is mixed with an extrusion aid to form a ‘paste’ and this is passed through an extrusion die at high pressure to attain the shape

-

Ram extrusion – where powder is added in successive charges into a die and a ram keeps compacting the powder such that a continuous profile is achieved

-

Compression moulding – where small profiles can be made (usually less that 1000mm in length) by simply compacting the PTFE powder within a die.

Both ram extrusion and compression moulding are employed when the diameters of the tube are in excess of 1” and when the final length needed does not exceed 2-3 meters. In case we want long lengths of tube, paste extrusion is the only option.

The length of a paste extruded tube is limited by the amount of powder that can be loaded into the extruder, since there is no option to add more powder once the extrusion begins. Most extruders would have a maximum capacity of about 10Kgs. Depending on the size of the thick-walled tube itself, the final length will be determined.

For the most part, paste extruded tubes are used to make thin-walled tubing, which is tubing where the wall thickness is within 2mm. The process for making thin-walled tubes follows a continuous sintering process, wherein the tube is extruded directly into the heating ovens and cured at the same rate at which it is extruded. This facilitates the need for a high structure to house the extrusion equipment. Typically, the extruder sits on the topmost floor, a drying oven on the floor below it and a sintering oven under the drying oven. Temperatures are set such that the drying oven is able to remove all traces of the extrusion aid (which is flammable) before the extruded tube reaches the sintering oven.

For higher wall thicknesses, there remain certain hurdles for paste extrusion in this manner. While extrusion itself is not a problem, the thick-walled tube is much tougher to sinter. The quantum of extrusion aid is high, owing to the high cross section of the tube. Hence, ensuring all removal of the extrusion aid in the drying oven is not guaranteed. This can result in fire when the tube reaches the sintering oven, where temperatures would be much higher than the flash point of the extrusion aid.

The other problem with thick-walled tubing is the weight of the tube itself. As thin-walled tubes are light, they place very little load on themselves during sintering, where the tube is soft. In contrast, the load of the thick-walled tube can result in it pulling on itself while in a heated state, causing stretching or deformation in the dimensions.

For this reason, separate sintering cycles and processes need to be developed for thick-walled tubing. Our own experience has shown that the drying and curing cycles need to be fine tuned to ensure that the tube remains uniform in dimension and does not crack or split during sintering.

Applications for thick-walled PTFE tube

Thick-walled PTFE tubes are used in areas where high burst pressures or high voltages exist. These applications include:

-

Pantographs for the railways

-

Insulation liners for heavy electricals

-

High-pressure pneumatic lines

-

Liners for high-wear applications

-

Shields for chemical equipment

The strength and insulative properties of PTFE ensure that it is often the only material of choice in applications involving strenuous environments.

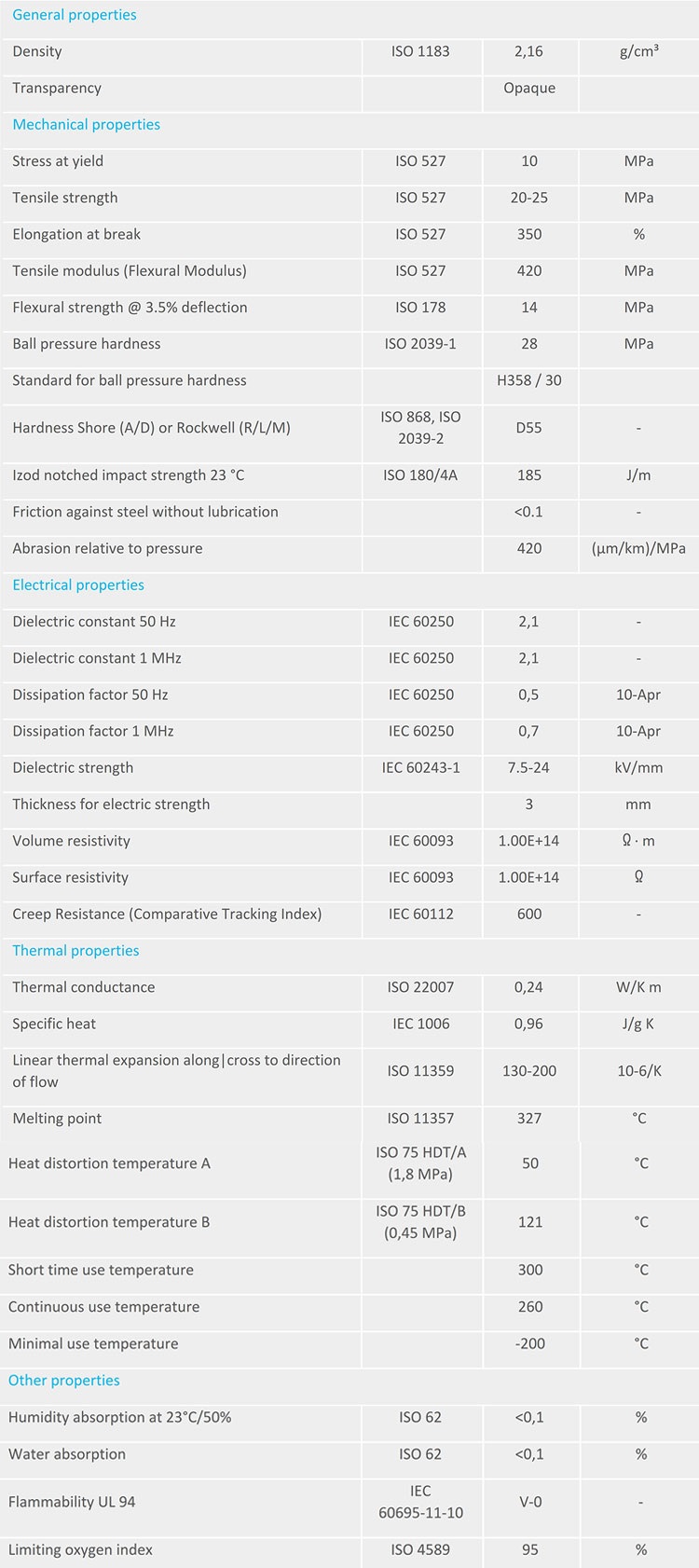

Properties of PolyTetraFluoroEthylene (PTFE) Thick-walled Tubes