The blending of polymers with additives is a common practice. There are very few materials that are used purely in their virgin form and PTFE is no exception here. Adding materials such a bronze, carbon and glass (to name but a few) have allowed us to augment the properties of PTFE to suit specific applications. In each case, we sacrifice some element of the original property of the PTFE, but enhance another. To take the case of bronze – the addition significantly increases the coefficient of friction of the PTFE and eliminates all electrical insulation properties. However, this is offset by a large and highly sought after increase in wear and hardness. Hence bronze filled PTFE is a preferred compound for a number of automotive and industrial applications.

In exploring what different additives do to the final properties of PTFE, we have found literature relating to materials such as those above, as well as less used additives such as molybdenum-di-sulphide, ekonol, stainless steel and graphite.

With the addition of PEEK, however, we find few sources with which to refer to on properties. While we do receive many requests for PEEK filled PTFE, the actual test data to support the compound is not easily obtained.

A 2006 paper titled: “A low friction and ultra-low wear rate PEEK/PTFE composite”, by David L. Burris, W. Gregory Sawyer, is all we have to refer to in this respect, but we will see that there are sufficient insights to help any OEM designer to assess the exact composition needed.

PTFE with PEEK fillers

We have come across a few applications where PEEK filled PTFE is the requested material. In most cases, what we receive is only a sample from the client. The light brown colour combined with the fact that the material “feels like” PTFE, is usually all we have to go with. Usually, the compound is used in sealing applications where high RPMs are involved.

Blending PEEK and PTFE

Unlike most other additives, PEEK blends with PTFE quite effortlessly. The lower particle size of PEEK (about 5microns against 25microns for PTFE) means that the grains of loose PEEK powder flow easily in between the PTFE grains and allow for a reasonably good blend. Further mixing is needed to ensure that the blend is uniform, but in our experience, it was less of a challenge to blend PEEK with PTFE than to blend pigments with PTFE.

Processing the material requires some minor fine tuning in the sintering cycle. However, when done properly, the resulting product is a very light brown that machines easily and offers some interesting properties.

Properties of PEEK filled PTFE

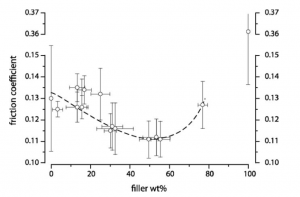

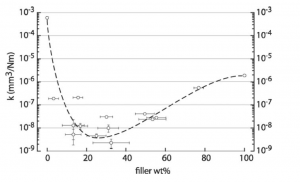

The paper by David L. Burris, W. Gregory Sawyer only looks into the wear and coefficient of friction of the blends of PEEK with PTFE. The paper looks at ratios (by weight) of 5%, 10%, 20%, 30%, 40%, 50% and 70%. The results obtained can be seen on the graphs below.

Coefficient of friction

Coefficient of Friction – PEEK filled PTFE

PTFE has a lower coefficient of friction than PEEK, so it would be reasonable to assume that the value keeps increasing with the addition of more PEEK. However, it is surprising to note that the coefficient is lowest at 50% of PEEK – at about 0.12.

It is important to mention than even at its lowest, the coefficient of friction is still much higher than for pure virgin PTFE(between 0.03-0.05). However, from a design standpoint, it is useful to know that adding a very small amount of PEEK is not the key to keeping the overall coefficient of friction as low as possible.

Wear resistance

Wear Resistance – PEEK filled PTFE

Again, given that virgin PEEK has better wear resistance when compared with virgin PTFE, we would assume that adding more PEEK keep improving this property. However, we again see that the best performing blend is PTFE+32% PEEK.

Conclusion

The above findings are useful from the point of view of grade selection. If an OEM wishes to design a seal using a combination that minimises the coefficient of friction and wear rates, they would be better off using a filler percentage close to 40%.