The transfer of fluids can be a complicated affair. In most applications that involve fluid transfer, the system is simultaneously subject to one or all of the following conditions:

-

High pressure

-

High temperature

-

Corrosive chemicals

Each of these conditions further compounds the effects of the other. For example, while a system may be equipped to handle high pressures, the added effect of corrosion can lead to ruptures or pinholes within the system that can cause failure. Hence, that any system that seeks to contain or transport fluids needs to ensure that all precautions are taken to accommodate the effects and minimise the risk of leakages.

Polymers are the preferred choice for fluid transfer applications for several reasons. First, there exist a huge range of choices that can be compared with the chemical properties of the fluid in question to ensure that the polymer does not react during functioning. A major issue with using metals is that even though they may not necessarily corrode, there is no guarantee that there will not be some reaction with the chemical fluids. Such reactions can alter the properties of the fluids themselves, which would be a problem. Polymers also operate at a wide range of temperatures and given that they are not as hard as metals, they invariably bring sealing properties that metals cannot match.

1. Polymer Seals

Seals can be machined from polymer stock shapes to match the tolerances of any system. Polymer seals are a vast area of application and can include everything from:

-

Ball valve seats

-

Spring-energised seals

-

Sealing rings

-

Chevron V-packings

-

Rotary seals

-

Linear sealing strips

There is no limit to the types of polymers that can be used in a sealing application. PTFE, PEEK, PPS (Ryton) and Polyimide seals are usually preferred in applications where there is a combination of high temperature and corrosive chemicals. In lower temperature applications (say, within 120°C), polymers such as POM (Delrin), PVC or even Polypropylene can be used.

The choice of polymer here is entirely application based. As always, it starts with the chemical compatibility and moves from there. For example, while PEEK is a very robust and machinable polymer, PPS is a preferred option in the paper and pulp industry. This is primarily because even though PEEK is chemically very inert, it does suffer some reaction to the chemicals used specifically in pulp and paper manufacture. With PTFE – which is easily the most chemically inert polymer – the issue is that of deformation. While PTFE can take high pressures – the combination of high pressure and temperatures can cause deformation in PTFE seals over time, leading to leakages.

2. Polymer valves

The function of a valve is to regulate the flow of fluids through a system. Not only does the valve need to ensure that there is a tight sealing around it (fluids should not be able to flow around the valve), but the valve needs to resist the fluids flowing through it and ensure that thermal expansion due to high temperatures does not hinder the smooth movement of the valve.

One application of PTFE valves is in the paints industry. Paint mixing machines use PTFE valves to regulate the flow of liquid paint. PTFE is the material of choice because paints are composed of myriad different chemicals. Each shade of paint would be a result of a specific combination of additives and it is therefore essential to have a material that does not react with what may be potentially thousands of different compounds.

PEEK valves are used extensively in coffee machines. The combination of high temperature liquids and food grade requirements means that PEEK – which is FDA approved – is a key material of choice. PEEK is also very thermally stable, which means that the valve does not expand (and therefore tighten) even when higher temperature liquids are passed through it.

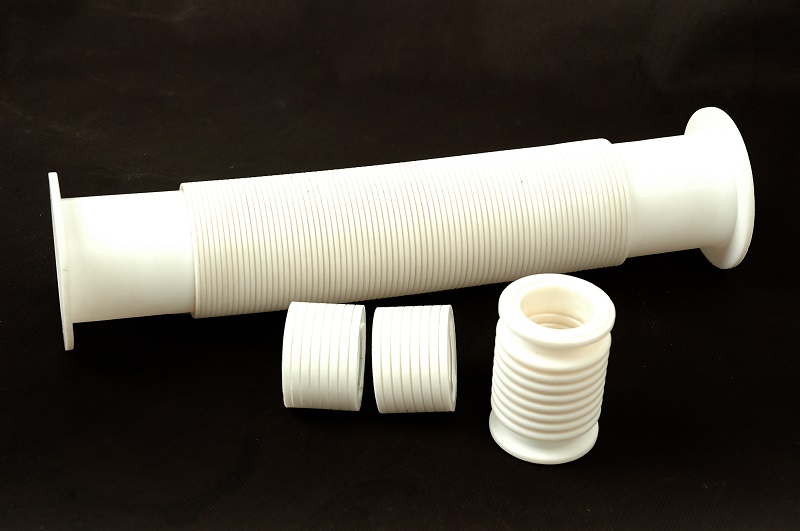

3. PTFE bellows

Bellows are complex parts that need to be machined out of PTFE. The key function of a bellow is to accommodate excess pressures and ensure that the system – typically a pumping system – does not fail over a long period of time. PTFE is used primarily because it is soft and because it is chemically inert. The softness of the material allows for the bellow to expand and contract, rather than succumb to higher pressures.

Different bellows have different ratings for the number of cycles that they can accommodate. However, a range of 1-2 million cycles is standard in the industry.

The only issue with a PTFE bellow is that because PTFE cannot be injection moulded, the bellow needs to be machined out of a block. This results in a wastage of nearly 80% on the material, making PTFE an expensive choice. Nonetheless, there are applications where nothing other than PTFE will suffice, and hence it is a preferred material in high-end chemical pumps.

4. ePTFE gaskets and gasket tape

Expanded PTFE, like regular PTFE, is an inert polymer that comes with a stellar ability to resist chemicals. The only drawback with regular PTFE is that it lacks the elasticity, or seal-ability, of some softer materials such as silicone or Viton rubber. However, these materials still cannot accommodate the high temperatures that PTFE can.

ePTFE gaskets and gasket tapes arrest some of the issues seen with regular PTFE in that it is highly compressible (up to 65%) and offers an excellent sealing between harder surfaces including metals and glass. More importantly, ePTFE provides sealing in high pressure applications of up to 100Bar, with minimal torque. This means that even more delicate assemblies can be fully sealed without having to put excess pressure on the bolted areas.

Both ePTFE cut gaskets and ePTFE gasket tapes are being increasingly adopted across fluid sealing applications. A combination of its ability to withstand high-temperature and high corrosion while offering high sealing makes it a material of choice.

5. Polymer bobbins

Some fluid sealing systems have a combination of metals and elastomers. For example, airline fluid systems use neoprene rubber for the transfer of fluids. In the event of fire or excess heat, it is essential that these rubber tubes be kept safe and away from metals – which can heat up quickly and melt the rubber easily.

Polymer bobbins are used as a medium to shield the rubber from the metals. Metal clamps – rather than being fitted directly on the rubber hose – will clamp around the bobbin which will then come in contact with the hose. This arrangement ensures that the bobbin, which can withstand higher temperatures and will not transfer heat, will keep the neoprene hose safe in the event that the clamp heats up, thus preventing a leakage that could have catastrophic effects.

6. PTFE (Teflon) Tubes

PTFE tubes are one of the most sought after for fluid transfer systems. PTFE tubes are resistant to chemicals and high temperatures. At the same time, the wall thickness of a PTFE tube can be enhanced to allow it to accommodate high pressures. Further, with stainless steel braiding, these pressures can be even higher.

PTFE tubes find application across industries such food processing, chemicals, electrical, and pneumatic lines, to name only a few.

A key example of the application of PTFE tubes is in analyser equipment. The equipment is used to evaluate the chemical composition of gasses that reach it though several tubes. Since the gas cannot be allowed to change its chemical structure in any way, it is essential that it travels through an inert medium that will not react with it. PTFE is an inert polymer, so, as there is no chance that the gas running through it will react with it and this ensures the purity of the system.

The above are but a few examples of high performance polymers and their applications in fluid sealing systems. For the most part, OEMs will design their own systems and then look for polymer solutions that specifically match their application. As such, there are literally thousands of different areas where polymers are used to ensure fluid systems are kept robust and free from leakages.