PTFE Tubes are known for their versatility and durability.

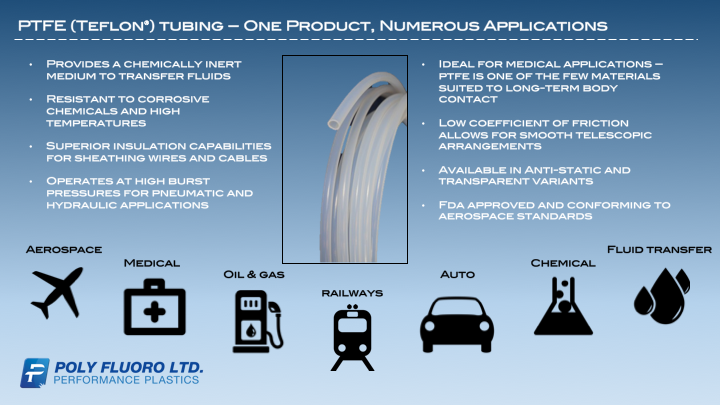

As a material, it comes with the numerous properties of PTFE, including temperature resistance, chemical resistance, electrical insulation and high-strength.

The high ratio of strength (both tensile and electrical) to weight gives us the option of using a much smaller tube of PTFE to do the same task that might require a lot more of a less capable material.

A high burst pressure means that both pneumatic and hydraulic systems would benefit tremendously from the use of PTFE tube. Similarly, a dielectric breakdown strength in the region of 150KV/mm implies that even a wall thickness as thin as 0.5mm allows for a breakdown resistance of 75KV.

Chemical lines, which often require a material that does not in any way react with the chemical inside it, benefit from the inert nature of PTFE. This means that even in the event that some unknown chemicals are present in the fluid passing through the tube, there is no risk that the tube will corrode or in any way impart its own reaction with the chemical.

PTFE tubes are known by many names across the industry:

They are all part of the same process and extruded in the same manner.

PTFE Tubing finds application in nearly every industry

Please visit our website for more details or email us: enquries@polyfluoroltd.com