In the realm of high-performance polymers, PEEK (Polyether Ether Ketone) and Polyimide stand out as two exceptional materials. Both are undoubtably among the toughest polymers, exhibiting tensile and flexural strengths far higher than even their nearest competitors. Given this, it is easy to see them as substitutes for one another and for an engineer to be confused over which one to choose in a given application.

Comparing chemical structure:

PEEK is a semi-crystalline thermoplastic known for its excellent mechanical properties, chemical resistance, and high-temperature stability. Its molecular structure imparts exceptional resistance to chemicals, abrasion, and wear.

On the other hand, Polyimide (often known by its brand names of Vespel or Kapton) is a high-performance polymer with a unique imide linkage in its molecular structure. This arrangement contributes to outstanding thermal stability, excellent dielectric properties, and exceptional resistance to radiation and chemicals.

Mechanical Properties:

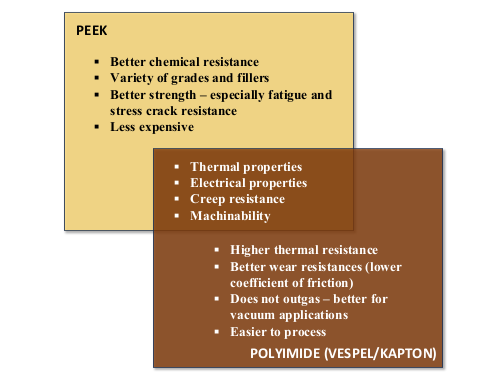

When it comes to mechanical properties, PEEK and polyimide both display distinct characteristics. PEEK offers a combination of high strength, stiffness, and toughness. Its tensile strength and modulus are comparable to some metals, making it a preferred choice in structural applications where mechanical integrity is crucial. PEEK's inherent toughness allows it to withstand repeated loading and impact without sacrificing performance. PEEK can also be enhanced with the addition of Glass, Carbon, and Graphite (Carbon-Graphite reinforced PEEK, also called HPV PEEK, is among the toughest polymer compounds known), which adds to PEEK’s versatility.

Polyimide, while not as stiff as PEEK, excels in maintaining its mechanical properties at elevated temperatures. Its ability to withstand prolonged exposure to high temperatures without significant degradation makes polyimide suitable for aerospace, electronics, and automotive applications where a combination of thermal stability at elevated loads is paramount.

When it comes to wear resistance, polyimide take the edge, as it exhibits a slightly lower coefficient of friction. While PEEK can be improved with the addition of PTFE, the base wear rate of polyimide is both low and constant over a range of loads. This means that in dry-running applications it is a better choice.

Thermal Stability:

Thermal stability is a key consideration in many high-performance applications, and both PEEK and polyimide offer exceptional heat resistance. PEEK is known for its thermal stability up to 260°C, making it suitable for applications in aerospace, automotive, and oil and gas industries. However, polyimide surpasses PEEK in terms of thermal stability, with some formulations capable of withstanding temperatures exceeding 300°C. This makes Polyimide the material of choice in extreme temperature environments such as electronics and aerospace applications.

PEEK boasts a high glass transition temperature (Tg) of around 143°C, making it suitable for applications in demanding thermal environments. However, polyimides typically exhibit a higher glass transition temperature than PEEK, often exceeding 250°C, making them more ideal for applications demanding extreme temperature resistance.

Chemical Resistance:

Chemical resistance is another critical factor in material selection, especially in harsh operating conditions. PEEK exhibits excellent resistance to a wide range of chemicals, including acids, bases, and hydrocarbons. It is also biocompatible. This makes it a preferred choice in chemical processing, medical, and oil and gas applications. Polyimide, with its unique molecular structure, provides outstanding chemical resistance, particularly against solvents, acids, and radiation. This property makes Polyimide suitable for applications in the aerospace, electronics, and semiconductor industries.

Cost and processing considerations

When it comes to cost, however, there is little need to compare the two. Polyimide’s key drawback is that it is prohibitively expensive. Polyimide is roughly 3-4X the cost of PEEK, which is significant considering that PEEK itself is about 20-25X the cost of more basic polymers such as POM or Nylons. Hence, most parts made from polyimides tend to be smaller and used sparingly in applications where PEEK does not make the cut.

Processing-wise, the other drawback of polyimide is that it cannot be injection moulded. It can only be compression moulded or extruded as a rod. This limits the complexity of parts that can be made when compared with PEEK. However, when we speak of compression moulding specifically, polyimide is more versatile and comparatively easier to process. While PEEK only lends itself to hot compression moulding (where the pressure and temperatures must act simultaneously), polyimide can also be cold compression moulded in a manner similar to PTFE. This allows for a much higher productivity, wherein material can be compressed and placed in an oven in batches, rather than moulded one at a time the way PEEK needs to be.

Conclusion

While it is fair to compare PEEK and Polyimide, the key consideration of cost means that PEEK usually wins out. However, there are certain applications where only Polyimide can be used and where cost may not be the biggest concern. It is likely that as polyimide gets cheaper (as polymers invariably do over time), the use cases will rise, and PEEK will have a worthy competitor.

Read More

1. PTFE Extrusion - Ram vs Paste Extruded - A comparison of features

2. Exploring the Versatile World of PVDF

3. Air Permeability Testing and Water Entry Pressure Testing in Expanded PTFE Membranes