The use of reciprocating compressors has become a mainstay for most industries. They form not only a vital part of any pneumatic or gas line but also feature in areas like refrigeration as the key part of the equipment or appliance.

Like most equipment, we seek constantly to limit the failure and downtime. While the break-down of a compressor can seriously hinder operations within an industrial outfit, failure within a consumer appliance can be very problematic, as we usually do not expect the compressor in a refrigerator or air conditioner to fail during the life of the product. Furthermore, the replacement of the compressor is expensive and time-consuming.

Analysis of the durability of this equipment yielded the failure of the compressor valve plate as one of the main causes of the breakdown.

The compressor valve plate sits at the heart of the reciprocating arrangement and is responsible for taking a lot of the loads associated with the compressor function. In addition to this, it is in direct contact with the air, gas or fluids running through the compressor and is subject to both corrosive forces as well as high pressures and temperatures.

Materials used in compressor valve plates

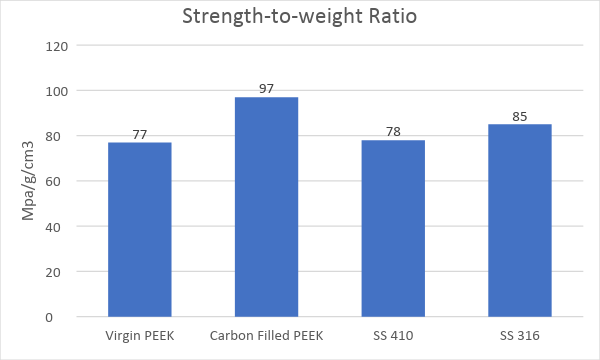

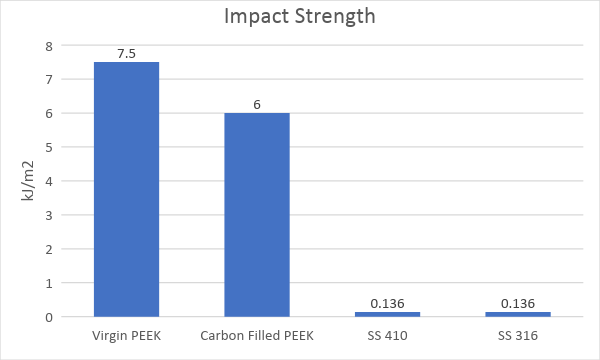

Traditionally, metals were used in this application. While metals are inexpensive, can withstand high impacts over a sustained period and are not affected by pressure or temperature, there were always concerns about corrosion. As newer fluids were developed, it became imperative to use materials that would not react in any way to a variety of chemicals that may pass through the compressor. Corrosion of the metallic compressor plates could also lead to chipping and fracture. While a fractured plate could be replaced ad hoc, any metal debris coming off the plate could find itself elsewhere within the equipment and cause additional damage.

Metal plates also do not perform well with ingress. A piece of dirt or grit – often unavoidable in industrial applications – can become lodged within the equipment, as a metal plate will not yield or absorb the particles into itself.

Polymers have been adopted as compressor valve plates from the 1960s. However, the hunt for the right polymer took nearly two decades more. The advantages of polymers became apparent once nylon was introduced. The key benefits were:

- Adequate impact strength

- Resistant to chemicals and temperatures up to 120°C

- Lightweight and inexpensive

- Better lubrication

- Easier to manage debris that may fall into equipment

- Ingress often absorbed into the material

While these advantages were understood, there were also other issues that prevailed, leading manufacturers to constantly look for better replacements.

Nylon

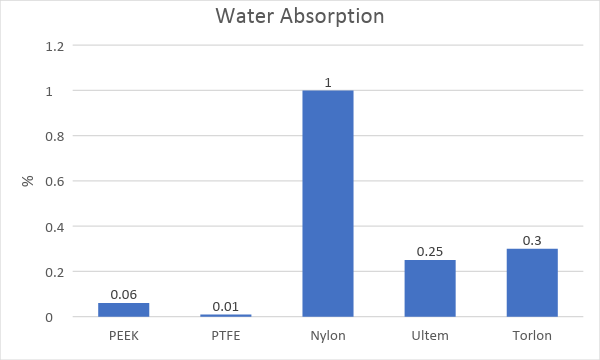

Initially, glass reinforced nylon was introduced. The key drawbacks here were temperature resistance and moisture absorption. Even with glass reinforcement, nylon still has a moisture absorption of close to 1%. This clearly causes issues as the valve plate swells and deviates dimensionally when exposed to moisture over a prolonged period.

At elevated temperatures nylon begins to degrade and can be attacked by acids and bases. Nylon also becomes brittle in oxygen-rich environments and as a result does not perform well in hot, moist gas service.

Polyetherimide (Ultem)

While Ultem clearly has the tensile strength, flexural modulus and temperature resistance needed, it suffers from issues with dimensional stability. Fundamentally, Ultem is an amorphous material – meaning its molecules are not locked into each other and can therefore move or slide over one another when under stress. This property means that over the life of the equipment, Ultem was unable to maintain serviceability.

Polyamideimide (Torlon)

Like Ultem, Torlon too checked a lot of the main boxes needed for this application, such as strength and overall durability. However, like Ultem, Tolron is also amorphous and like Nylon, it has a relatively high water absorption. The crystalline properties of Tolron can be increased by special processing, such that the molecules lock more rigidly. However, under heat, any absorbed moisture tends to swell the material from the inside, causing dimensional deviations in the long term.

PEEK – the ultimate choice for compressor valve plates

By the 1980s, PEEK had been around long enough and tested across enough applications to confirm that it was a potentially great candidate for compressor valve plates.

While PEEK exhibits a tensile strength at par with the toughest of polymers (reaching, in some compositions, to nearly metal-like levels of toughness), its crystalline structure ensures a level of dimensional stability even after years of operation.

PEEK is resistant to temperatures of up to 300°C, which goes well beyond what might be needed in this application. It is also resistant to a wide variety of chemicals and is affected only by concentrated nitric and sulphuric acids, which are highly unlikely to be present within a compressor.

PEEK’s water absorption, at 0.06%, is also far less than that of any of the above polymers.

The addition of fillers such as glass and carbon only enhances the properties of PEEK further, making it the right material for this application.

Overall, the introduction of PEEK into this application has seen a vast improvement in efficiency and durability, leading to reductions in maintenance costs and machine down time.