Polymers in Renewables - The Rising Role of High-Performance Plastics in Renewable Energy

- Updated on :

- Poly Fluoro Ltd

- Comment

As the world takes a conscious and collective stand against the rising use of fossil fuels, it also disrupts a status quo set in place during the dawn of the industrial revolution. Since fossil fuels began to power our homes, factories and cars, most technological developments have focussed merely on efficiency gains. The improved productivity of coal-fired power plants, combined with better refining techniques and higher efficiency engines have allowed us to do more with less. At the same time, demand has moved steadily upwards, implying that even with these productivity gains, costs have always been rising.

The biggest hurdle to renewable energy was always the fixed costs involved. Consider a solar, or wind-powered plant. Not only is there no option to run these plants 24x7, but the cost per unit of power produced, when added to the cost of the infrastructure itself, always lagged the numbers showcased by their traditional, fossil fuel counterparts. However, efficiency gains have been made in renewables as well. In fact, one might argue that while we have somewhat plateaued with the gains in fossil fuel productivity, the gains in renewables are only just getting started. As a result, the earliest solar plants are now starting to show net positive gains when compared with coal power plants. The same can be said for wind and hydroelectric power plants.

Assisting in this wave of continual improvements in efficiency and productivity are polymer materials that lend their properties to this endeavor. Here we look at a few ways in which high-performance polymers are contributing to the field of renewable energy.

1. Solar Tracker Bearings

The effectiveness of a solar panel in maximizing the energy it can harvest is improved by ensuring it receives the highest intensity of sunlight possible. Solar tracker systems are designed to rotate the solar panels in order to keep them facing the sun at an optimal angle. However, the energy expended in rotating the panels cannot exceed the efficiency gains from the rotation itself. Thus, it is critical to have a low-cost, low-friction process that limits the energy consumption of the tracker.

Solar tracker bearings are made using high-performance, UV resistant polymers that are both light-weight, low in cost and easy to install. In addition to this, we have developed solar tracker bearings that employ fiction reducing additives, leading to higher efficiency gains in the system. Cost-wise, the bearing assembly can be made at roughly 1/10th the cost of a traditional metallic bearing.

2. Bearings for wind turbines

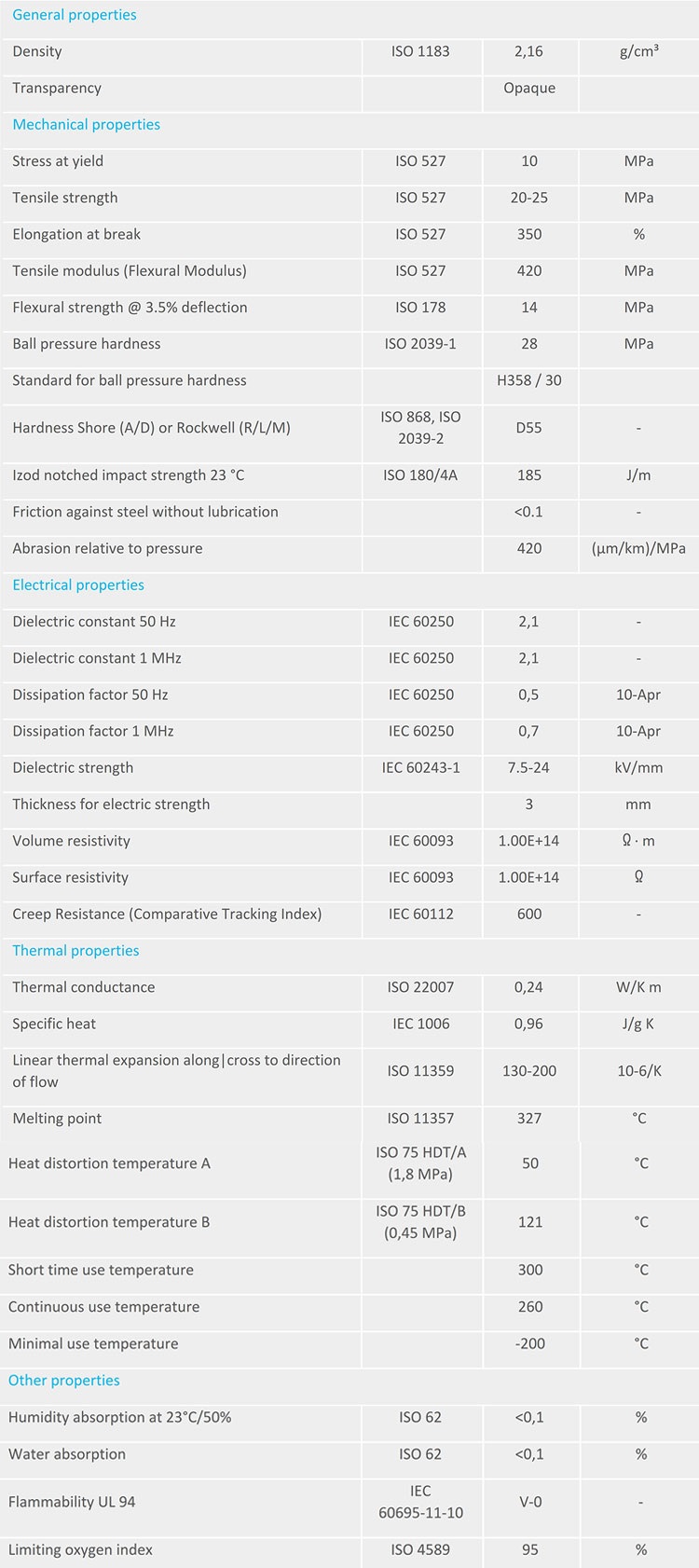

Like solar tracker systems, wind turbines too have a tracking system which maximizes the angle of the turbine to ensure it receives the most energy. In addition to this, the process of harnessing wind energy is a rotary process, implying higher RPMs and a need for lower friction. Any friction in the system immediately results in a net energy loss. Hence, high-performance polymers such as PTFE find use in these applications. Although PTFE can be an expensive material, the coefficient of friction it offers can be as low as 0.03 when moving against polished stainless steel. This allows a simple PTFE bearing to take on loads and prove effective in applications where otherwise heavy and more expensive metal assemblies would be needed. Furthermore, as PTFE is a self-lubricating material, the need for grease and/or constant maintenance is significantly reduced. This is especially useful for wind turbines, which are usually located in remote areas and benefit from needing less maintenance.

3. EV charging stations

Electric Vehicles are gaining traction over traditional fuel powered vehicles. As their demand and prevalence grows, so too would the infrastructure needed to ensure that they can function smoothly. Investments in EV charging stations have increased significantly and new housing developments are increasingly required to ensure that there are charging stations for all parking slots.

As a superior insulation material, PTFE has been found effective in EV charging stations. PTFE insulation blocks can be used to improve the charging efficiency and ensure that there is minimal leakage of current.

4. Battery separators

One of the key factors with renewable energy is that storage needs to be both ample and efficient. While traditional power plants feed directly into the grid, solar and wind plants will only generate power in bursts. As a result, a lot of effort has gone into battery technologies. Both PTFE and PE (polyethylene) are seen as effective battery separators.

These separators provide internal insulation to the battery, preventing the batteries from discharging when idle. Although PE separators are effective in most applications, high-voltage applications need PTFE films, which possess higher breakdown voltage strengths and can remain effective over a much longer time period. These PTFE films can be made in thicknesses of as low as 40 microns and have breakdown voltages of as high as 100KV per mm.

5. Plastic to diesel conversion - renewable polymer fuels

While polymers are certainly effective in improving the efficiency of renewable energy systems, the irony is that most polymers are manufactured from fossil fuels themselves. However, recent advancements in plastic-to-fuel technologies have allowed waste polymers to be converted back into combustible fuels. While this does not exactly fall in the same category as renewables, it does allow for a lot of waste plastics to be re-used, rather than end up in landfills.

The above are but a few applications where polymers are finding use. In truth, there are myriad different areas when the properties of high-performance plastics can be utilized to improve, enhance and augment existing systems of renewable energy.