The advent of precision CNC technology has allowed us to machine components to ever closer levels of tolerance. Metal parts, in particular, will lend themselves to tolerances as close as 1µm (1 micron), or 0.001 millimeters. Not only can such tolerances be attained, but on a piece of stable, well-maintained equipment, their repeatability is guaranteed.

In contrast to metals, polymers do not conform to such close tolerances. Depending on the polymer in question, a variety of factors, including the heat build-up during machining, stress in the underlying material, and the impact of moisture can all play havoc on dimensions. Hence, when we see tolerances of less than 20µm on a customer drawing, we know that the part designer comes from a background in metals and does not appreciate the near impossibility of maintaining the repeatability of such a dimension on a polymer.

Note that we say, ‘near impossibility’ and not an impossibility. This is because with experience and a lot of trial and error, polymers too can be machined to as little as 10µm tolerances. It is not easy and requires a significant amount of care and caution during machining, but it is possible.

Machining PTFE

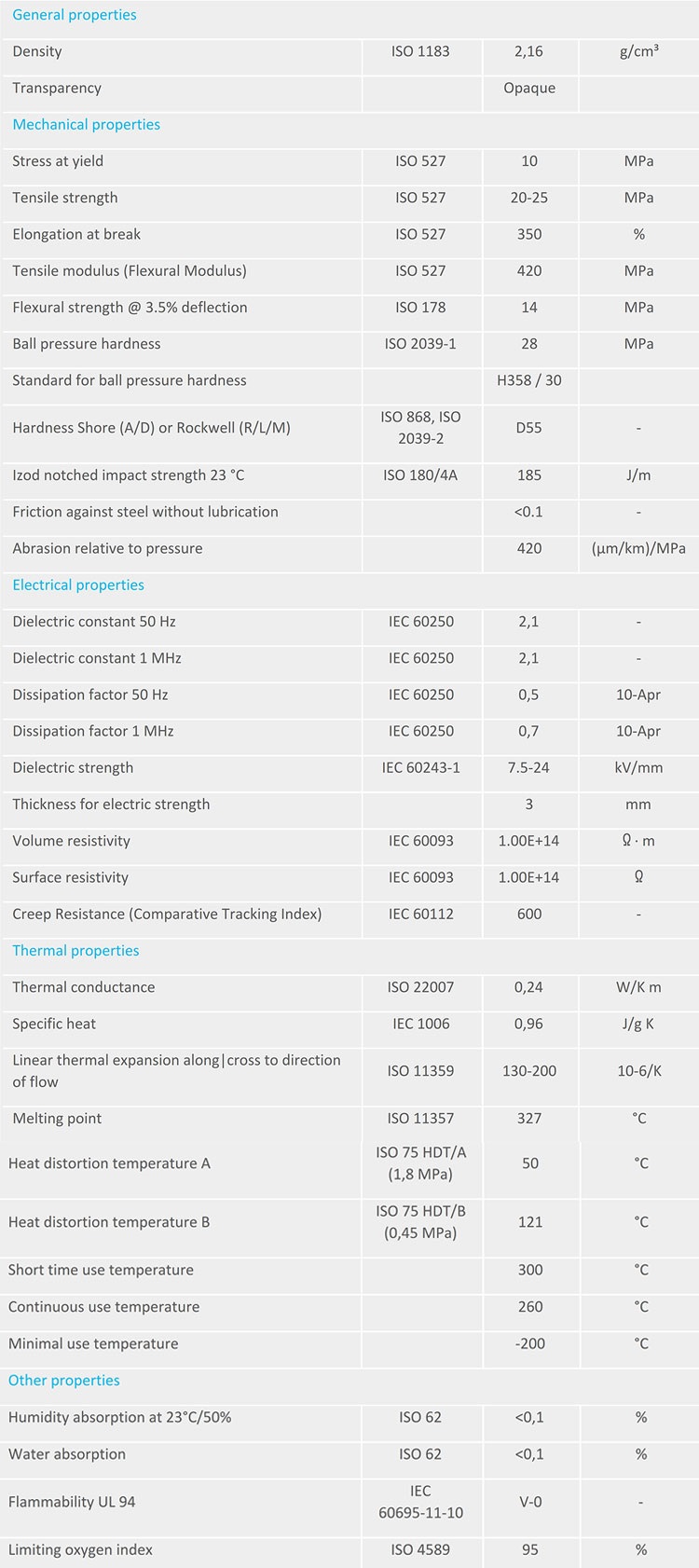

PTFE (Teflon) exhibits such a range of properties that it finds use in nearly every industry. As a component – either a valve, seal, seat or a ring – it can be machined either from its raw (virgin) form, or it can be combined with special fillers that add other properties to the material, but which also complicate the machinability of PTFE. Here are some of the key factors to consider when machining PTFE to close tolerances.

1. Filler

The filler changes the composition of the PTFE material and as a result, it affects the behaviour both during and after machining. A filler such as glass, offers higher dimensional stability and the ability to machine down to as little as a 10µm tolerance. Fillers such as carbon and graphite cause the PTFE to become very coarse at a molecular level, resulting in extensive damage to the tool tip. As a result of this damage, the tool itself loses effectiveness and can result in the parts going out of spec.

Fillers are usually employed because they alter the properties of the base PTFE material. Glass is used to improve hardness and reduce creep, while carbon and bronze are used to improve wear resistance.

2. Sinter cycle

The sinter cycle is a vital part of how PTFE is processed and has a tremendous impact on the PTFE properties. Depending on the size of the part, a cycle of anywhere from 14 hours to 72 hours can be employed. The sintering cycle heats the PTFE up to its melting point, allowing the particles to fuse together. Then the cycle cools the part steadily to ensure that the parts do not crack. A cracked part cannot be re-used, and it is therefore vital from a cost perspective to get the sinter cycle right. Certain blends of PTFE may require a high or lower peak temperature and also a gradual or sharper cool down rate. Once the part comes out of the oven, the easiest thing to check for would be the tensile strength, hardness, specific gravity, and elongation. If these are matching specifications, the material can be considered acceptable.

However, apart from curing the part, the sinter cycle is also vital in how the part behaves both during and post-machining. For one, a part may exhibit good tensile properties, but may still suffer from over-shrinkage after machining. Our own experience has been that parts that exceed 200mm (8”) in diameter need to be observed after machining for shrinkage. In case the part exhibits excessive shrinkage – say over 0.2mm – then attention needs to be given to the sintering as the part may need to be run on a longer cycle to arrest this issue.

In addition to dimensional stability, the part may also exhibit ovality post sintering. This is especially true for larger parts. The issue with ovality is that the part may not clear during machining. Hence, a post sintering re-shaping may be needed to ensure the part is evenly round. However, too much reshaping can also cause problems. Because PTFE has memory, it is likely to try and come close to its original shape over time or when exposed to high heat. In our experience, a temperature of even 150°C for one hour (well below the 250°C service temperature of PTFE) can cause the part to try and regain its post-sintering shape. Hence, care needs to be taken to minimise the ovality at the sintering stage itself or ensure that any re-shaping does not try and alter the part so much that it loses dimensional stability when on the field.

3. Tooling and environment

The type of tooling, machining process (RPM, feed rate, program) and post machining storage all lend themselves to the repeatability of critical dimensions. Very often, we believe that hard, durable tool tips will give us the best and closest finish on the part. However, in many cases we have seen a simple HSS tool tip offer superior results to the more expensive carbide tips.

Similarly, the RPM and feed rates both work towards improving the part dimension and finish. A high RPM may offer a better finish, but may also result in heat build-up, which may show up only post-machining. Hence, each part needs to be treated specially to ensure all the parameters work together for the best possible result.

In addition to tooling, note that PTFE is highly sensitive to temperature. Very often, shrinkage can be attributed to nothing more than a change in the climate. Since PTFE can experience a dimensional change of up to 3% between 0 and 100°C, it is not uncommon to see large parts exhibit shrinkage of a few tenths of a millimetre, when the weather becomes cooler or warmer over a few days. The only way to address this is to ensure that the part is inspected under temperature-controlled conditions.

There are other aspects of machining PTFE that we do not delve into here. Needless to say, as a material, it is as versatile in its processing techniques as it is in its end-properties. However, as a valuable and integral part of so many systems, it makes sense to understand and appreciate these processes so that a consistent and high-quality end-product can be manufactured.