Expanded PTFE (ePTFE) Tapes - Properties and Installation Techniques

- Updated on :

- Poly Fluoro Ltd

- Comment

ePTFE Tapes are an ideal form-in-place gasket material made from 100% pure virgin PTFE that has been expanded to achieve a foamy structure.

While we have covered the applications of this earlier and also touched upon some of the variants, we would like to re-explore some of the finer aspects of the material as well as look at the installation in more detail.

ePTFE Structure

A number of variables contribute to what we would define as a suitable final product. While the nuances of the production technique are proprietary information, what we can reveal is that the end product, while seemingly uniform, can be anything but.

- Specific Gravity In achieving a final product that matches the properties of other ePTFE Gasket Tapes in the market, one of the key properties explored was the density of the material. By varying the process, this parameter can be altered to produce different results. While most commercially available ePTFE Tapes have a specific gravity of 0.6-0.7, we were able to bring this down to 0.3, making the material much softer and more malleable.

This reduction in density is not always preferred. In applications where the ePTFE is sandwiched between steel elements, you would prefer a higher specific gravity. However, in delicate applications, such as electronics and medicine, we may need to use a gasket or sealing element upon which large pressures cannot be applied as the equipment themselves are fragile. In such cases, a low density tape would be ideal as it would take the shape required with minimal pressure

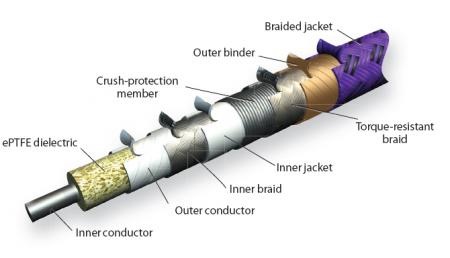

- Thickness Standard ePTFE tapes come in thicknesses starting from 1.5mm. However, certain applications such as cable wrapping and filtration require tapes as low as 0.1mm in thickness. While achieving was not easy, it did allow us to explore the properties of tapes under 1mm in thickness and gauge what made them so different.

ePTFE Tapes fall somewhere between sintered PTFE tapes (made from skiving a fully sintered PTFE billet) and thread sealant tape (made from calendaring unsintered PTFE strips). As such, they imbibe the electrical properties of skived tapes, while retaining the malleable structure of thread sealant tape. Furthermore, the foamy structure allows for better thermal insulation as compared to both the other variants

- Fillers Fillers are commonly used in PTFE to attain variations in final properties. We have experimented with fillers of PEEK and Carbon to reveal variations that significantly improve what the ePTFE tapes are capable of. Carbon allows us to make anti-static tapes, which are used extensively in the manufacture of co-axial cables. PEEK, meanwhile allows for vastly improved wear properties, while not violating any dielectric parameters or FDA parameters.

In addition to this, we will be looking at fillers of glass and graphite. Each will bring its own unique alterations to the material.

Sizes available

FluoroFoam ePTFE gasket tape is an ideal solution for flange connections, container rims, and any other metal to metal application requiring a compressible, chemically resistant seal.

The tape comes with a one-side adhesive that aids in the installation by allowing exact placement of the gasket lining.

| Standard Spool Lengths (others on request) | ||||

| Size (mm) | 5m | 10m | 25m | 50m |

| 1.5 x 3 |  |

|

||

| 2 x 5 |  |

|

||

| 2.5 x 7 |  |

|

||

| 3 x 10 |  |

|

|

|

| 4 x 12 |  |

|

|

|

| 5 x 14 |  |

|

||

| 6 x 17 |  |

|

|

|

| 7 x 20 |  |

|

|

|

| 5 x 25 |  |

|

|

|

| 5 x 28 |  |

|

||

Installation guidelines:

Completely clean the sealing area and remove any dirt, corrosion, oil or leftover from old gasket material.

Cut one ending of the sealing tape and remove just a little of the protecting paper. Place the tape at the nearest possible position next to the bolts, starting next to a bolt hole. Fit the gasket around the entire flange circumference and across the endings as shown in figure 1.

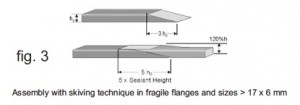

Assembled in fragile flanges apply techniques as shown in figure 2. Skive the endings as shown in fig. 3 and overlap according to the recommended overlap length. Cut off the excess, tapering to the end, leaving a total thickness of approx. 120 %.

At least 4 progressive torque sequences with a torque wrench, in a star of 180° (fig. 1), should follow the first torque by hand.

Lastly, perform a circular torque to check and ensure a tight and long-lasting seal.

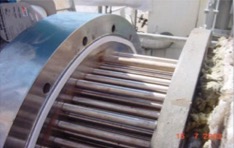

Photos of typical applications:

The ePTFE Tape is allowed to overlap at the ends to ensure complete sealing.

Due to the softness of the tape, this overlap is accommodated during compression causing no variation in thickness

The one-side adhesive backing allows installation even on vertical surfaces, eliminating the need for grooves, clamps or bolting arrangements.

Metal-to-metal flange connections benefit greatly from the use of FluoroFoam ePTFE.

The ePTFE takes the exact shape of the gap between the two metal members ensuring a perfect seal with minimal effort

Form-in-place ePTFE gasket tape can effectively seal flanges on large shell-and-tube exchangers

Available in running lengths – the tape saves big on cost in areas where large, custom made gaskets would be too expensive

The versatility and texture of the material ensure that there is no shape that cannot be attained.

This adds to the effectiveness as well and reduces costs significantly compared with custom made gasket and sealing solutions

Advantages of FluoroFoam ePTFE Gasket Tape:

- Quick and simple installation: adhesive strip makes installation easier while the shape and versatility of the material means minimal cutting and sizing

- Reduced downtime: standard sizes are immediately available ex-stock

- Reduced stock: a few spools of different sizes cover most applications within a plant

- No risk: the texture of FluoroFoam ensures the material accommodates the shape of the mating member, so there is no chance of the equipment getting damaged by the ePTFE

- Safe: ePTFE is chemically inert and can, therefore, be used even in the harshest environments without risk of reacting with the surrounding substances

- No waste: FluoroFoam comes in a spool, so no material gets wasted

- Cost-effective – FluoroFoam can be used to replace custom made gaskets that are expensive and made-to-order. This is results in a huge cost saving in larger diameter pipes and vessels.

Technical Details:

- Temperature range: – 240°C up to +260°C, for short periods up to +310°C

- Chemical resistance: resistant against all chemicals from pH 0-14 – except molten alkali metals and elemental fluorine at high temperature and pressure

- Pressure resistance: vacuum up to 200 bar

- Density: 0,65 g/cm³, +/- 0,1g/cm³ (for rectangular cross-sections only)

- Aging resistance: FluoroFoam itself does not age and is UV-resistant. However, the adhesive backing may lose its effectiveness if kept unused for too long

- Colour: white (other pigments available on demand)

- Fillers: FluoroFoam can be offered in virgin and carbon filled variants

- Others: FluoroFoam is physiologically harmless. It has no smell or taste. It is neither contaminating nor toxic. It is made using FDA approved raw materials